As the demand for electronics continues to grow, the amount of e-waste across the globe is also increasing dramatically. According to statistics, the global e-waste generation has reached 62 million tons in 2022, an increase of 82% from 2010. According to forecasts, this figure could reach 82 million tons by 2030.

E-waste contains a large number of recyclable precious materials, such as metals, semiconductors and rare elements, which can provide significant value for resource recycling. But worryingly, only about 22.3% of e-waste was properly recycled and disposed of in 2022, and the rest of the materials worth about $62 billion were discarded directly and ended up in landfills.

While efforts are being made around the world to improve the recycling of e-waste, the recycling process is still complex and labor-intensive. What's more, much of the e-waste ends up being exported to developing countries that use cheap labor for recycling, which often involves the use of harmful chemicals that pose great risks to the environment and human health.

To improve the efficiency of e-waste recycling, especially copper wires in recycling cables, a new study proposes an innovative approach. In the journal RSC Advances, researchers from Sophia University in Japan and the University of Pavia in Italy published their latest research results – a pyrolysis recovery technology based on microwave heating. This technology offers a new, cost-effective way to recycle wires and cables.

Research Methods:

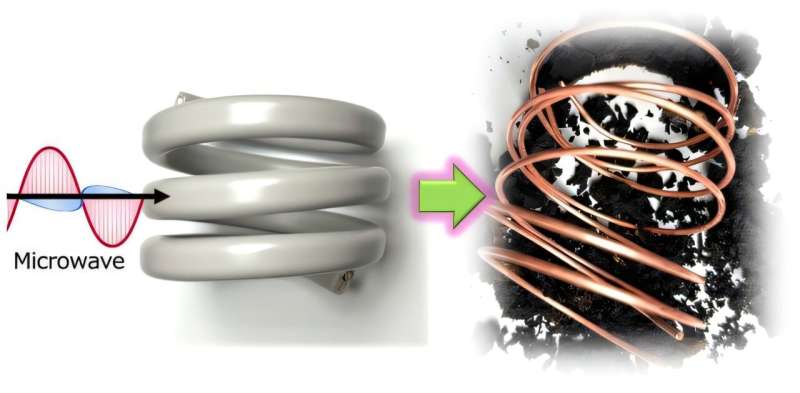

At the heart of this new technology is the use of microwave radiation to heat and decompose the PVC insulation of the cables, ultimately exposing the copper wires for easy recycling. Specifically, the researchers placed the cables in a glass reactor and used 100, 200 and 300 watts of microwave radiation to heat the cables. By introducing nitrogen, they avoid combustion during the heating process.

In the experiment, the researchers used a twinax cable containing two PVC-insulated copper wires, which are often used as power lines in houses and buildings and have a high recycling value. The researchers also cut the cables in different lengths, including cable segments of different lengths such as 1 cm, 6 cm, 9 cm, 12 cm, and 18 cm, and tested the effect of microwave pyrolysis on these different lengths.

Figure: Microwave pyrolysis technology: a new breakthrough in improving the efficiency of e-waste recycling

Effect of microwave pyrolysis

Interestingly, the effect of microwave pyrolysis varies with the length of the cable in relation to the microwave wavelength. At the frequency of 2.45 GHz, the wavelength of a microwave is about 12.24 centimeters. It was found that the pyrolysis effect was most pronounced when the length of the cable was close to or greater than this wavelength. In particular, the 9 cm and 18 cm long cables start pyrolysis in just 60 seconds at 100 watts of microwave power. In contrast, cables with shorter lengths (e.g., 3 cm) require higher power (200 watts) to start pyrolysis, while some cables with lengths close to wavelength (e.g., 1 cm, 6 cm, and 12 cm) fail to pyrolyze effectively, even at the highest power.

The principle of pyrolysis

The reason for the best pyrolysis effect is related to the length of the cable, the action of the copper wire, and the strength of the electric field. Specifically, copper wires act as antennas in these cables, capable of absorbing microwave radiation and creating arc discharges that heat the PVC insulation without damaging the copper wires. In addition, when microwave heating, the strength of the electric field is strongest at both ends and in the center area of the cable, which allows these places to be heated faster and more intensively. As the PVC layer is heated and gradually carbonized, its ability to absorb microwaves is also enhanced, further accelerating the pyrolysis process.

Prevent harmful by-products

In this process, the PVC insulation undergoes dechlorination and carbonization, effectively preventing the formation of harmful by-products such as tar, polycyclic aromatic hydrocarbons (PAHs) and dioxins. Another advantage of this process is that chlorine can be recycled and converted into hydrochloric acid, while the carbon and activated carbon produced by pyrolysis can be recycled as carbon black.

The dual advantages of efficiency and environmental protection

With this microwave-assisted pyrolysis method, the researchers succeeded in completely breaking down a 54-centimeter-long cable in 12 minutes using 300 watts of microwave power, without any damage to the copper wire. A significant advantage of this method is that it does not require pre-treatment of the PVC cable, which saves a lot of time and labor costs.

Currently, about 35% of the world's PVC plastic material can be recycled, and this new method significantly improves the efficiency of recycling copper wire and effectively reduces the negative impact on the environment. Therefore, this microwave-assisted pyrolysis technology not only enables more efficient and economical recycling of copper wires from e-waste, but also provides a practical solution to the growing problem of e-waste.