In 2025, the AI manufacturing industry may usher in epoch-making changes. Three industry giants, NVIDIA, Foxconn and UBTECH, jointly announced that they will deploy humanoid robots at Foxconn's AI factory in Houston, Texas, USA, in 2025 to produce NVIDIA's high-performance AI servers. This cross-border cooperation is not only a model of technology integration, but also a milestone event in the global "AI + manufacturing" integration trend.

Ⅰ. "Robot Production AI Server": Leapfrog application landing

The biggest highlight of this cooperation is that humanoid robots will be directly applied to the intelligent manufacturing of AI servers. Different from traditional robotic arms, humanoid robots have higher flexibility and environmental adaptability, and can handle complex, high-precision assembly tasks, especially for multi-interface, high-density, and complex electronic products such as NVIDIA AI servers.

According to Nvidia's official website and Reuters, Nvidia's AI server shipments will continue to grow in 2025, and the share of the global AI server market is expected to exceed 60%. This deployment plan just solves the growing pressure on the production of computing power equipment for NVIDIA, and also injects stronger flexible manufacturing capabilities into its AI factory.

In terms of UBTECH, its humanoid robot Walker S released in 2023 can perform a variety of complex tasks including precision assembly, touch control, navigation and obstacle avoidance, and will enter the industrial scene in 2024. Foxconn also officially announced in 2024 that it will build a new AI factory in North America to meet the needs of customers such as NVIDIA and Amazon in localized manufacturing.

This "three-strong combination" not only realizes the deep integration of GPU computing power, flexible manufacturing and humanoid robot technology, but also marks the first large-scale entry of humanoid robots into the main line of semiconductor manufacturing, representing the transformation of intelligent manufacturing from "auxiliary role" to "auxiliary role" Main workers" forward.

Picture: Nvidia × Foxconn× UBTECH: Jointly build a 2025 humanoid robot AI manufacturing model factory

Ⅱ. Why can humanoid robots be "competent as AI factory workers"?

In traditional manufacturing, although robotic arms have been widely used, their adaptability is insufficient—especially in complex assembly scenarios such as AI servers, which still require a lot of manual intervention. Humanoid robots offer a flexible and intelligent solution:

*Flexible joint + multi-modal perception system: UBTECH's industrial-grade humanoid robot has more than 40 degrees of freedom, hand accuracy of ±0.1mm, built-in high-definition vision system and haptic feedback system, which can handle multi-type interface plugging and unplugging, motherboard fixing, cable management and other operations.

*Intelligent decision-making + cloud-edge collaboration: The Jetson Orin series embedded computing platform and Isaac Sim simulation system provided by NVIDIA can provide real-time path planning, task scheduling and system diagnosis capabilities for robots, and realize multi-robot collaborative operation.

*Adaptive ability + long-term operation: Through the continuous optimization of the action trajectory through the AI model, the humanoid robot can adapt to the actual working conditions such as part model changes and station adjustments. Foxconn's pilot data shows that in 48 hours of continuous operation, the error rate of the robot is controlled below 0.1%, which is significantly better than that of human and traditional automation equipment.

According to industry insiders, during the trial operation of the project, the production efficiency increased by 35%, the error rate of key stations decreased by 62%, and the labor cost was saved by more than 20%. This makes it the next generation upgrade paradigm of manufacturing automation after the SMT (Surface Mount Technology) automatic line.

Ⅲ. A model of industrial chain synergy: how to divide labor and coordinate tripartite cooperation?

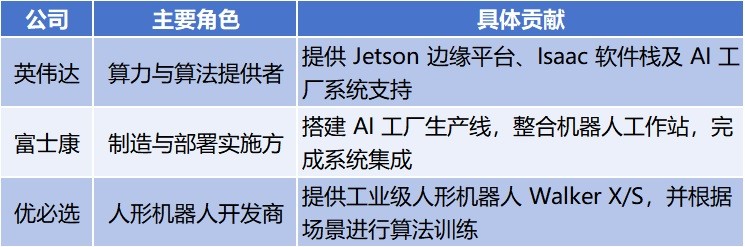

The plan is not only a technical integration, but also a highly organized industrial chain collaboration, with the three parties performing their respective duties:

Picture: NVIDIA, Foxconn, UBTECH, the three parties perform their own duties

This collaborative mechanism breaks the boundaries of traditional enterprises and forms a highly integrated "intelligent manufacturing community". For the entire semiconductor manufacturing chain, this model is expected to be extended to wafer fab clean environment auxiliary operations, module testing, SMT back-end automatic detection and other links.

Ⅳ. the three major challenges on the eve of change: the implementation still needs to overcome technical and cost barriers

Despite the grand concept, there are still many challenges to realize the large-scale deployment of humanoid robots in AI factories:

1. The system stability and fault recovery mechanism need to be improved

At present, although humanoid robots are making continuous progress in research and development, their reliability still needs to be verified for long-term continuous work. Problems such as sensor redundancy, task interruption recovery, and equipment thermal management in complex environments need to be further optimized.

2. Costs are still high and ROI (return on investment) cycles are long

At present, the cost of a single industrial-grade humanoid robot is between 250,000 and 400,000 US dollars (including ontology and integrated commissioning), which is slightly higher than that of traditional automation equipment. To achieve the deployment of more than 50 units, the initial investment will exceed 10 million US dollars. For most manufacturing companies, the payback cycle is still an important consideration.

3. There is a shortage of compound technical talents, which has become a bottleneck for landing

"AI+ manufacturing" engineers who truly understand the logic of robot behavior, can debug AI algorithms, and have experience in factory scenarios are extremely scarce. According to a report released by McKinsey in 2024, the global robotics industry chain is expected to have a compound talent gap of more than 150,000.

These problems determine that the project will still be in the stage of demonstration verification and small-scale mass production in 2025, and whether it can be fully promoted still depends on the effectiveness of systematic optimization and the speed of improvement of ROI.

Ⅴ. New paradigm of AI manufacturing: future trends and application prospects

Despite the challenges, this cooperation undoubtedly points out a clear direction for the future manufacturing model - humanoid robot + AI factory + localized manufacturing

* In the manufacturing process, humanoid robots are expected to replace more repetitive manpower including plug-ins, inspections, and packaging in the future;

*Under the trend of globalization, with the "local manufacturing" strategy of NVIDIA and other enterprises, the complexity of the supply chain and cross-border transportation costs can be greatly reduced;

*In terms of technology evolution, with the improvement of the performance of AI inference chips and the optimization of robot motion control algorithms, the threshold and cost of AI inference chips will continue to decrease.

Goldman Sachs predicts that by 2035, the annual output value of the humanoid robot market will exceed 38 billion US dollars, of which manufacturing and logistics will be the first two areas to benefit.

Conclusion: Humanoid robots have become the main workers in manufacturing, and a new era has emerged

The 2025 Houston Humanoid Robot AI Factory Project, which is a tripartite collaboration between NVIDIA, Foxconn, and UBTECH, is a far-reaching experiment. Not only will it bring more efficient and flexible production methods to the semiconductor industry, but it may also be the harbinger of global manufacturing transformation.

The future of AI manufacturing is no longer just about people controlling machines, but machines having the ability of "people".

We may be witnessing the next industrial revolution.