Ⅰ New product release: integrated packaging breaks through the bottleneck of power density

ROHM Semiconductor today announced the development of a new silicon carbide (SiC) power module in a HSDIP20 package, consisting of 4-in-1 and 6-in-1 integrated solutions, covering 750V (6 models) and 1200V (7 models) voltage levels, specifically designed for power factor correction (PFC) and LLC converters for on-board chargers (OBCs) for electric vehicles (xEVs). By integrating the basic circuitry required for power conversion in a compact package, these modules significantly reduce the design burden on manufacturers and enable miniaturization of power conversion circuitry for applications such as OBC.

Ⅱ Core performance: heat dissipation and integration efficiency are improved

1. Significant optimization of heat dissipation

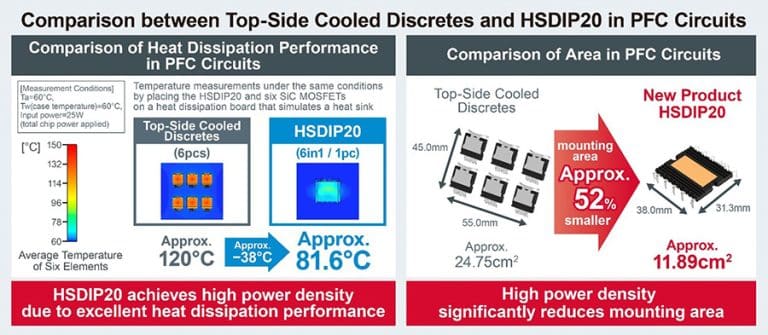

By being equipped with a highly thermally conductive insulating substrate, the HSDIP20 module can effectively suppress chip temperature rise during high-power operation. In a PFC circuit test of a typical OBC (25W input power, 60°C ambient temperature), the average temperature of the 6-in-1 module is reduced by approximately 38°C (approximately 120°C vs. HSDIP20 approximately 81.6°C for the discrete solution) compared to a solution with 6 top-cooled discrete SiC MOSFETs, resulting in a significant increase in heat dissipation.

2. Breakthrough in power density and space efficiency

Power density: The HSDIP20 has an industry-leading power density, which is more than 3 times higher than top cooling discrete solutions and 1.4 times better than comparable DIP modules.

Mounting area: In PFC circuits, the installation area of the HSDIP20 is reduced by about 52% compared to the discrete solution (about 24.75 cm² vs. HSDIP20 about 11.89 cm² for the discrete solution), which greatly reduces the size of the power module and meets the needs of electric vehicles for lightweight and compact design.

Figure: ROHM develops a new high-power-density silicon carbide power module

Ⅲ Market background and application scenarios

1. Driven by demand in the electric vehicle industry

As vehicle electrification accelerates, battery voltages increase to extend range and charge speeds, creating a need for higher output power and smaller size for OBC and DC-DC converters. The bottlenecks of traditional discrete device solutions in terms of power density and heat dissipation are becoming increasingly prominent, and integrated modules have become the key to breaking the game.

2. Diversified application expansion

Automotive: on-board chargers, electric compressors and other electric vehicle power systems.

Industrial & Consumer Electronics: EV charging stations, V2X systems, servo motors, server power supplies, photovoltaic inverters, etc., can be widely used in scenarios that require efficient power conversion.

Ⅳ The value of technology and future planning

The HSDIP20 module uses system-in-package (SiP) technology to achieve multi-device co-optimization in a single package, balancing the needs of high performance and miniaturization, and providing a new idea for the power design of electric vehicles and industrial equipment. ROHM said that in the future, it will continue to promote the research and development of miniaturization and efficiency of SiC modules, and focus on the development of automotive SiC intelligent power modules (IPMs) to further improve reliability and reduce size to support the energy transition needs under the global carbon neutrality goal.

Summary

ROHM's HSDIP20 series modules address the pain points of traditional discrete solutions in electric vehicles and industrial applications with leading thermal performance, high power density, and integrated design, and are expected to accelerate the popularization of SiC technology in the field of new energy and promote the development of more efficient and compact power systems.