The semiconductor industry is ushering in an unprecedented wave of change. With the rapid development of artificial intelligence and the exponential growth of computing demand, chiplet technology is becoming a key breakthrough in the design of next-generation chips. However, the widespread implementation of this technology is not only a problem of the technology itself, but also an economic proposition about the balance between value and cost. Whether the core can move from cutting-edge innovation to the mainstream of the industry ultimately depends on whether it can build a sustainable economic system.

In fact, the future of the chip is based on three core pillars: deployment, design innovation, and manufacturing implementation. These three not only carry opportunities and challenges independently, but also need to form a closely coordinated ecological closed loop to promote the maturity of core technology.

1. Deployment pillars: from high-end pilots to mainstream scale

The primary challenge of chip technology is to move out of the "high-end silos" and achieve commercial-scale deployment. If a sufficient amount of market application cannot be formed, even if the technology is advanced, it is difficult to share the cost, and it is impossible to form a virtuous circle of the industrial chain.

At present, chips have made initial breakthroughs in scenarios such as high-performance computing and data centers. These applications are a natural fit for the strengths of die technology in terms of performance, energy efficiency and modularity, especially in the context of a distributed architecture and the need for "use on demand" for advanced processes. However, relying on these "beachheads" alone is not enough.

The automotive industry, and the rise of autonomous driving technology in particular, could be the next big tipping point. In the future, emerging scenarios such as augmented reality (AR/VR), humanoid robots, and edge computing will also put forward higher requirements for the integration of computing, storage, sensing, and communication.

However, from a small-scale pilot to a large-scale adoption, there are still a number of challenges to overcome: reducing costs, improving reliability, and ensuring full lifecycle security. These goals can only be achieved through widespread deployment.

2. Innovation Pillar: Fission Growth of Design Ecology

The world of die design is experiencing an unprecedented peak of innovation. The synergy between EDA (Electronic Design Automation) tools and IP (Intellectual Property) modules has led to a significant increase in the number of designs based on pre-validated components, as well as a rapid increase in system complexity and functional diversity.

The reason why this innovation flywheel works well is the fierce competition between EDAs and IP providers. They continue to introduce new tools and modules that support die architectures, opening up unprecedented possibilities for designers. What used to be considered sci-fi is now becoming a reality.

However, there are concerns about this explosive innovation. If rapid design iteration does not keep pace with manufacturing capabilities and actual deployment, it can lead to a "design-manufacturing disconnect" and a large number of ideal solutions that can only be drawn on drawings and difficult to mass-produce. Therefore, the imagination of design must evolve in tandem with the reality of the industrial chain.

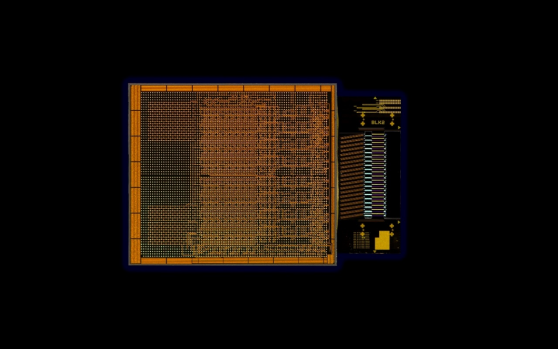

Figure: Economic Logic in the Chip Era: A Blueprint for the Future from Technological Breakthroughs to Ecological Reconstruction

3. Manufacturing Pillar: Turning complex ideas into real products

Manufacturing and testing are a key part of the application of cores. It not only carries the mission of transforming design into products, but also bears the ultimate test of cost control and quality assurance.

Under the chip architecture, design complexity and manufacturing variability have increased simultaneously, and the traditional "pre-design prediction" thinking has become difficult to cope. The introduction of advanced packaging technologies has further exacerbated the challenges, especially in the areas of high-density interconnects, thermal management, and reliability testing, which place extremely high demands on the process.

At this stage, data becomes a key resource. From the design end to the manufacturing end and then to the testing link, opening up the data chain of the whole life cycle and building a predictive model with the help of artificial intelligence technology is becoming the core path to improve manufacturing efficiency and product quality. Applications such as adaptive testing, predictive grading, and aging modeling indicate that the manufacturing process is entering the "intelligence-driven" stage.

4. Collaborative Ecology: From Fragment Competition to System Integration

What supports the long-term development of the core economy is not only the strengthening of the three pillars themselves, but also the deep integration and co-evolution between them.

At present, each player in the semiconductor industry often works in silos, focusing on its own cost efficiency and KPIs, ignoring the impact on the overall system performance. This fragmented situation is difficult to meet the development needs of the cross-domain and cross-professional technical architecture of the chip.

In the future, there is an urgent need to build a neutral and open platform to break down the data barriers between EDA, IP, manufacturing, and fabless enterprises, so that data can become a universal language, and system collaboration can truly occur at the intersection of values. Only in this way can the potential of core technology be fully unleashed and the entire industry can enter a new era of collaborative innovation.

5. Conclusion: What defines the future is not only technology, but also systems

Chips are not only a design method, but also a reshaping of the logic of the semiconductor industry. A successful chip-based economy requires a virtuous cycle between the three pillars of "Deployment-Innovation-Manufacturing" to achieve the co-evolution of technology and market.

Enterprises and countries that can master this collaborative ability will occupy a dominant position in the future chip landscape. Those who fail to keep up with this pace of change may be obsolete by the new wave of technology.

The future of chipping does not depend on the success of technology, but on our ability to build the economy and ecosystem that underpins its success. This is not only a crossroads of industry choice, but also a systematic test of organizational collaboration, value reconstruction, and strategic patience.